The Cost Per Equivalent Unit Calculator simplifies this process, enabling users to calculate costs effectively. This article will explain the formula, how to use the calculator, provide an illustrative example, and answer common questions related to the topic. This report shows the costs used in the preparation of a product, including the cost per unit for materials and conversion costs, and the amount of work in process and finished goods inventory. A complete production cost report for the shaping department is illustrated in Figure 8.71. The concept of equivalent production units is widely used in various industries, such as manufacturing, mining, agriculture, etc. While the basic principle of calculating equivalent units of production remains the same, some variations in the calculation method depend on the specific industry and the nature of the production process.

Create a Free Account and Ask Any Financial Question

Often there is a different percentage of completion for materials than there is for labor. As described previously, process costing can have more than one work in process account. Determining the value of the work in process inventory accounts is challenging because each product is at varying stages of completion and the computation needs to be done for each department.

Accounting for Managers

Those are considered 100% complete for the work done in that department, otherwise they wouldn’t be moving forward to the next process. As with calculating the equivalent units and total cost of production in the initial processing stage, there are four steps for calculating these costs in a subsequent processing stage. Accurate costing is crucial for the calculation of equivalent units of production. Companies should use an appropriate costing method, such as process or job costing, and ensure all costs are assigned to the proper production units. EUP provides a more accurate picture of production output and cost analysis, as it considers partially completed units and provides a way to compare the cost of production to the number of units completed. Equivalent units of production assume that all units produced are of equal quality.

Physical Units

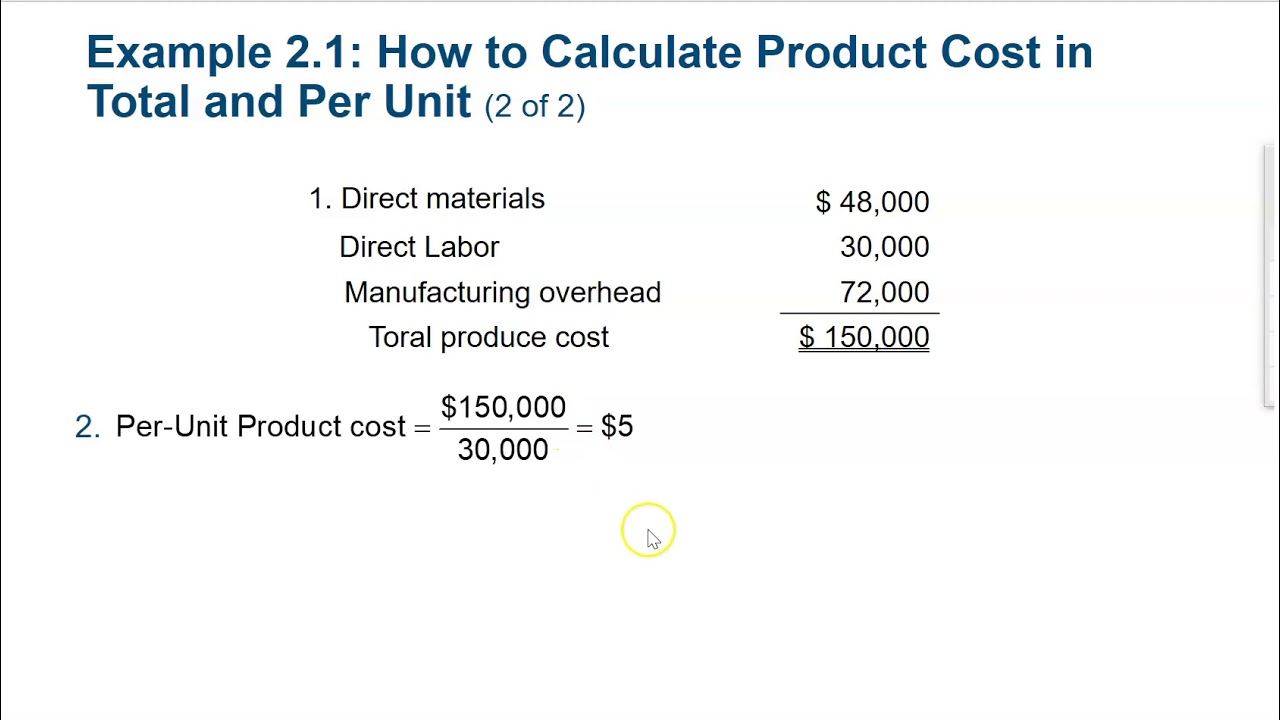

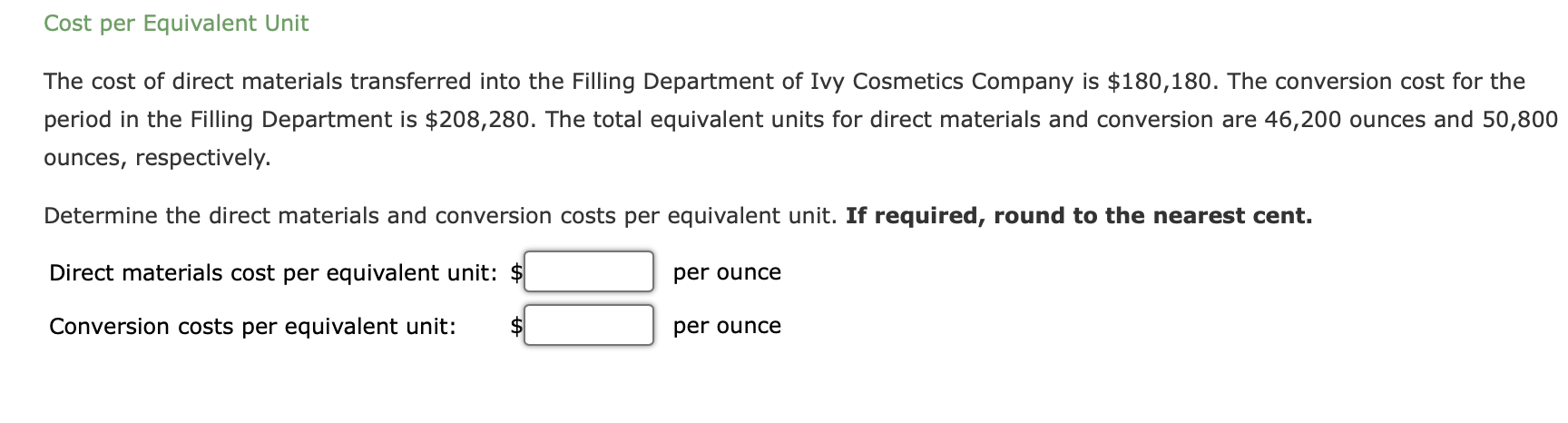

First, we need to know our total costs for the period (or total costs to account for) by adding beginning work in process costs to the costs incurred or added this period. In managerial accounting, determining the cost per equivalent unit is essential for understanding production costs in manufacturing processes. This metric helps businesses assess the efficiency of production and allocate costs accurately.

In continuous processes, there is work-in-progress at the beginning and end of a period, as well as a degree of completion of closing work-in-progress. The calculation goes to four decimal places, because when you’re making candy that sells for 20 cents per unit, and you’re producing hundreds of thousands of units, every tiny fraction of a dollar counts. This video will provide a demonstration of cost assignment under the FIFO method. Textbook content produced by OpenStax is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike License . Our mission is to empower readers with the most factual and reliable financial information possible to help them make informed decisions for their individual needs.

For example, forty units that are \(25\%\) complete would be ten (\(40 × 25\%\)) units that are totally complete. It is instrumental in process costing, where the production process is continuous and involves multiple stages of production. By calculating the EUP, businesses can accurately estimate their production costs and determine the value of their inventory at different stages of production.

It is a little different, however when there is a beginning and ending number of units that have been partially finished. These goods in process must have costs allocated to them along with the goods that were finished during the period. While revolving funds for financing water and wastewater projects EUP can help analyze the cost of production, it may not always reflect the actual costs incurred by the business. For example, EUP does not consider the cost of rework or defects, which can significantly impact the overall cost of production.

- The concept of EUP assumes that partially completed units are equivalent to a certain number of complete units.

- The problem will provide the information related to beginning work in process inventory costs and units.

- Essentially saying, that process 1 completed 850 units to completion of process 1 in this period.

- EUP can identify areas of the production process where capacity is underutilized or overutilized.

In that case, it can be challenging to determine the equivalent production units for each period. If the closing work-in-progress is 800 units, 70% complete in all respects, the equivalent units of production of closing work-in-progress is 560 units (i.e., 800 x 70%). In cost accounting, equivalent units are the units in production multiplied by the percentage of those units that are complete (100 percent) or those that are in process. In this method, both the beginning and ending inventory is converted into equivalent units, so there is a bit more work to do. For those units that were in the beginning inventory, we need to figure out how much work was DONE on them in this period to get them to the point of being transferred to the next process. For those items in the ending inventory, it is the same as the weighted-average method, where we need to calculate how much work has been done to them already.

The costs for material and conversion need to reconcile with the total beginning inventory and the costs incurred for the department during that month. First, we need to know our total costs for the period (or total costs to account for) by adding beginning work in process costs to the costs incurred or added this period. Then, we compare the total to the cost assignment in step 4 for units completed and transferred and ending work in process to get total units accounted for. In the previous page, we discussed the physical flow of units (step 1) and how to calculate equivalent units of production (step 2) under the weighted average method. We will continue the discussion under the weighted average method and calculate a cost per equivalent unit.

It can help ensure that each product is assigned a fair share of the costs and can help prevent over- or under-reporting of equivalent production units. Companies should have clear and well-defined production processes to ensure all production units are accounted for and accurately measured. It can help minimize errors and inconsistencies in calculating equivalent production units. The variations in calculating equivalent production units in different industries reflect each sector’s unique characteristics and challenges. Regardless of the industry, however, using equivalent production units is valuable for measuring and managing production processes and costs. In some industries, such as mining, the output may be measured in different units, such as weight or volume.